Your commercial Energy Storage System (ESS) is offline at 3 AM, or your forklift battery dies before lunch. It’s a familiar scenario where an unexpected low battery problem derails operations and spikes costs. We understand industrial battery anxiety, especially when millions in revenue are at risk.

As a battery expert, I aim to cut through the guesswork. We’ll move beyond the dead cell to identify the root cause, covering the culprits, providing immediate fixes, and outlining the long-term strategies that genuinely boost cycle life** and performance.

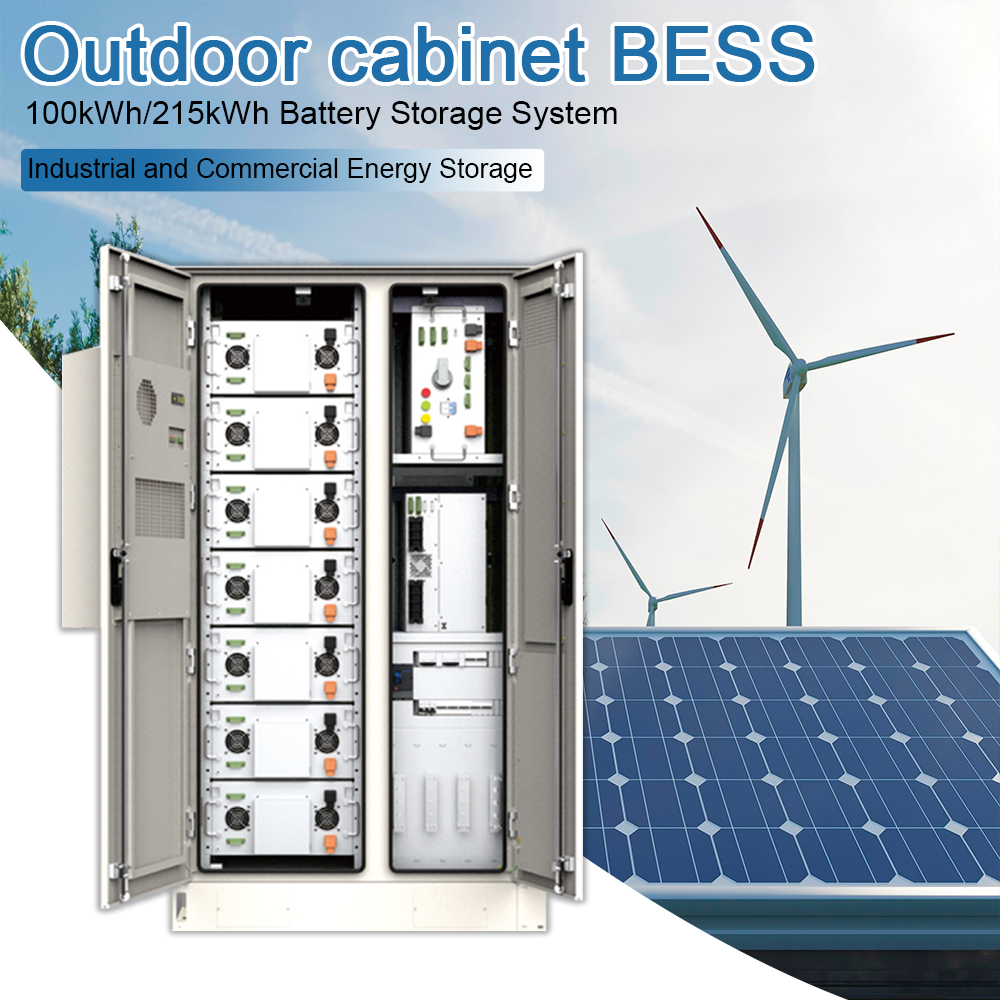

100kwh Commercial Energy Storage System

12v 100ah lifepo4 battery

12v 200ah sodium ion battery

The Low Battery Landscape: Common Symptoms & When to Worry

When an industrial battery begins its failure process, the symptoms, quite frankly, can often be subtle before they ever become catastrophic. For B2B buyers, recognizing these early indicators is absolutely crucial; their timely detection, naturally, prevents costly downtime.

| Symptom | Application Example | Implication |

|---|

| Slow Cranking/Starting | Marine backup power generators | The battery can’t deliver the necessary Cold Cranking Amps (CCA) under load; terminal corrosion may also be present, for one thing. |

| Rapid Percentage Drop | Industrial equipment (e.g., automated guided vehicles) | Severe capacity fade or issues with the Battery Management System (BMS) state-of-charge calculation are evident. |

| Device Shutdown Under Load | Power tools or high-demand portable devices | Internal resistance is simply too high, causing the voltage to collapse dramatically during high current draw. |

| Physical Swelling or Overheating | Any Lithium-Ion battery pack | Urgent Warning! This indicates an irreversible chemical reaction or a thermal runaway risk. Isolate the pack and replace it immediately—no exceptions. |

The most critical distinction, of course, rests between sudden failure (which often suggests a short circuit or parasitic drain) and gradual degradation, which is merely physics running its inevitable course. Regarding industrial assets, tracking performance curves remains non-negotiable—for instance, while your sodium-ion battery pack may lose 5% capacity annually, and that’s expected degradation, losing 20% in a single month means you certainly face an urgent technical fault.

Deep Dive: Common Causes of Low Battery

Understanding the “why” gives you, the engineer, the expert’s advantage here. You see, low battery status, interestingly enough, isn’t exclusively about age; often, the way the system interacts with the battery itself proves to be the true cause.

Chemical Degradation & Age (The Inevitable Cause)

Every single battery, without exception, possesses a finite life, but the exact cause of that endpoint, we know, differs based on its chemistry.

- Lithium-Ion Capacity Fade: The loss of available lithium and cathode material over time primarily causes this, something that happens over thousands of cycles. This is precisely the reason why your older industrial tablet barely lasts half a shift.

- Lead-Acid Sulfation/Stratification: This is the buildup of lead sulfate crystals, a process which actively impedes chemical reactions. This phenomenon often kills forklift batteries that maintenance personnel do not regularly equalize.

Quick Fact: While many consumer batteries carry a warranty for 1–2 years, quality LiFePO₄ batteries for stationary storage often achieve 3,000–6,000 cycles, potentially pushing the lifespan to well over a decade, provided users manage them correctly.

Parasitic/Phantom Drain (The Sneaky Killer)

This occurs when systems continue drawing power even after operators turn them “off.” In the industrial space, this frequently results from a software or hardware oversight, often subtle.

- BMS Standby Current: For advanced battery packs (like those found in a 100kWh Battery C&I ESS), the BMS itself draws a small, constant current to continually monitor cell health. Should an ESS or large pack be left untouched for many months, this cumulative drain can eventually drive cells below their safe voltage threshold—a major concern for long-term storage.

- Faulty Components: A sticky relay or even a dimly lit indicator on an off-grid inverter can, over time, bleed amps for weeks.

Pro Tip (Experience): Based on our extensive experience working with industrial clients, the fastest way to trace a phantom drain on a large system is to measure the current draw directly at the battery terminals, and then isolate the loads one by one via fuses or breakers.

Environmental Stressors (The Weather Impact)

Temperature, undeniably, silently assassinates battery longevity.

- Extreme Cold: In low temperatures, the electrolyte thickens, slowing down the chemical reactions, and severely reducing the battery’s ability to deliver current. For instance, a battery rated for 100 Ah at 25℃ might only deliver 50–60 Ah at 0℃. This becomes especially critical for equipment operating in cold storage or northern climates.

- Extreme Heat: High temperatures accelerate internal degradation rates, chemically destroying the battery faster.

Expert Insight: The optimal operating temperature range for most Lithium batteries hits 20℃ – 25℃. Any sustained operation above 35℃ will significantly shorten cycle life.

Charging Habits & User Error (The Preventable Mistakes)

Users often make preventable mistakes that damage batteries over time.

- Frequent Deep Discharges: Running the battery down to 0% repeatedly stresses the anode and cathode materials, in effect, permanently reducing capacity.

- Overcharging/Wrong Chargers: Using non-compatible or faulty chargers can overcharge cells, causing heat damage and potential swelling.

- Leaving Electronics On: Operators sometimes leave small accessory loads on, which then drains the battery over hours or days.

Sometimes you don’t need a full audit; the thing is, what you need is simply a way to get the asset back online quickly.

For Automotive Emergencies (Generator Backup/Fleet Vehicles)

- Safe Jump-Starting Procedure: Always connect the positive (+) cable first, then the negative (-) to the non-battery vehicle ground last. While a simple jump-start is often the quickest fix if the battery is merely discharged, it is certainly not a solution for degradation itself.

- Testing the Alternator: If the vehicle immediately dies after removing the jumper cables, the alternator—which, remember, functions as the battery charger—is likely the problem, not the battery itself.

For Mobile/Portable Devices

- Solution 1: Users can, quite simply, “force restart” the device and close background apps immediately.

- Solution 2: Switching to Low Power Mode and reducing screen brightness directly cuts power draw.

The Charging Trick (Expert Experience)

Should a Li-ion or LiFePO4 Battery Pack (such as a standard 12V 100Ah Lifepo4 Battery) see a deep discharge (i.e., below 2.0V per cell), the BMS may lock it out for safety—it simply won’t respond to a standard charger.

Quick Fix: Some sophisticated chargers offer a “wake-up” or “low-voltage recovery” mode; it applies a very low, steady current to bring the voltage back into a safe range before commencing a full charge. Safety Warning: Attempting this with an unknown or non-certified charger is dangerous and can potentially cause an over-current situation.

Long-Term Battery Health & Prevention

Prevention, ultimately, is the absolute best solution. Your procurement and maintenance strategy, therefore, must focus on extending service life.

The 20-80% Rule (Optimal Charging Zone)

Expert Rationale : Keeping a battery’s State of Charge (SoC) between 20% and 80% dramatically reduces internal stress. Operating at the voltage extremes (near 0% or 100%) places the greatest strain on the active materials. This is key for systems where capacity—and thus cost—is critical, for example, large sodium-ion battery packs entering the market as a cost-effective alternative to LiFePO₄. While LiFePO₄ is robust, all Li-ion chemistries benefit from avoiding these extremes.

Smart Storage Practices

- Maintaining a charge level (e.g., 50%) for long-term storage definitely helps preserve capacity.

- Storing batteries in a cool, dry place prevents accelerated degradation.

When to Replace: The Expert’s Indicators

Replacement is a capital expenditure decision. Base it strictly on data—that’s the key—not on guesswork.

- Key Indicator: You should replace the battery when its SOH (State of Health) falls below 80% capacity of its original rating. At this point, the operational trade-offs—shorter run-time, increased charging frequency—usually outweigh the remaining value.

- Checking Health: Most modern BMS provide a direct reading of SOH. For older batteries, a simple discharge test under a controlled load remains the only reliable way.

Conclusion

Solving low battery problems requires moving past the symptom; you absolutely must address the root cause, whether it’s routine degradation, a sneaky parasitic drain, or poor extreme temperature performance. By focusing on proper BMS monitoring, maintaining an optimal charging window, and replacing assets when they hit that 80% SOH threshold, you effectively transition from reactive failure management to proactive maintenance optimization. Don’t let battery uncertainty dictate your operational efficiency.

Need a second opinion on your fleet’s SOH or evaluating a new battery supplier? Contact kamada power battery。

FAQ

What are the main differences between low battery causes in industrial LiFePO₄ and older lead-acid fleets?

The causes differ significantly. Low battery in a lead-acid system usually results from irreversible sulfation because operators left the battery discharged or performed poor maintenance. Low battery in a LiFePO4 battery pack more often results from a BMS fault (e.g., it misreads SoC) or a deep discharge that the BMS has locked out for safety. Lead-acid dies slowly and chemically; LiFePO₄ often dies suddenly and electronically.

How can I stop a constant parasitic drain on my industrial equipment?

Poor shutdown procedure or a faulty accessory causes the most common industrial parasitic drain. Start by installing a battery disconnect switch when you store equipment long-term. For active equipment, use a multimeter to measure current when the system is supposedly “off.” If the current is above the manufacturer’s specified standby range, you’ll need to isolate subsystems (like the telemetry unit or primary controller) one by one to find the culprit.

Can I mix older and newer battery packs in a single commercial ESS setup?

Generally, no, you shouldn’t. Mixing batteries with different SOH or cycle life ratings forces the newer, healthier battery to perform at the level of the oldest, weakest one. This creates charging imbalances, overstresses the older pack, and prematurely reduces the performance of the entire Energy Storage System. It’s always best practice to replace and commission battery strings in uniform sets.