Production lines stop. A flicker of the lights, a motor whining down—that’s all it takes for an operation to halt. That downtime costs money, erodes margins, and jeopardizes deadlines. A brief grid failure shouldn’t shut down your entire operation.

This is where industrial battery energy storage systems (BESS) become critical. They are not just backup power. They are a tool for managing energy costs, hardening your facility against outages, and meeting sustainability goals. The market is full of options and the technology can seem intimidating.

This guide gives buyers and engineers a clear roadmap. It’s not a sales pitch. The goal is to equip you with the core concepts and an actionable plan to decide if a BESS makes sense for your facility.

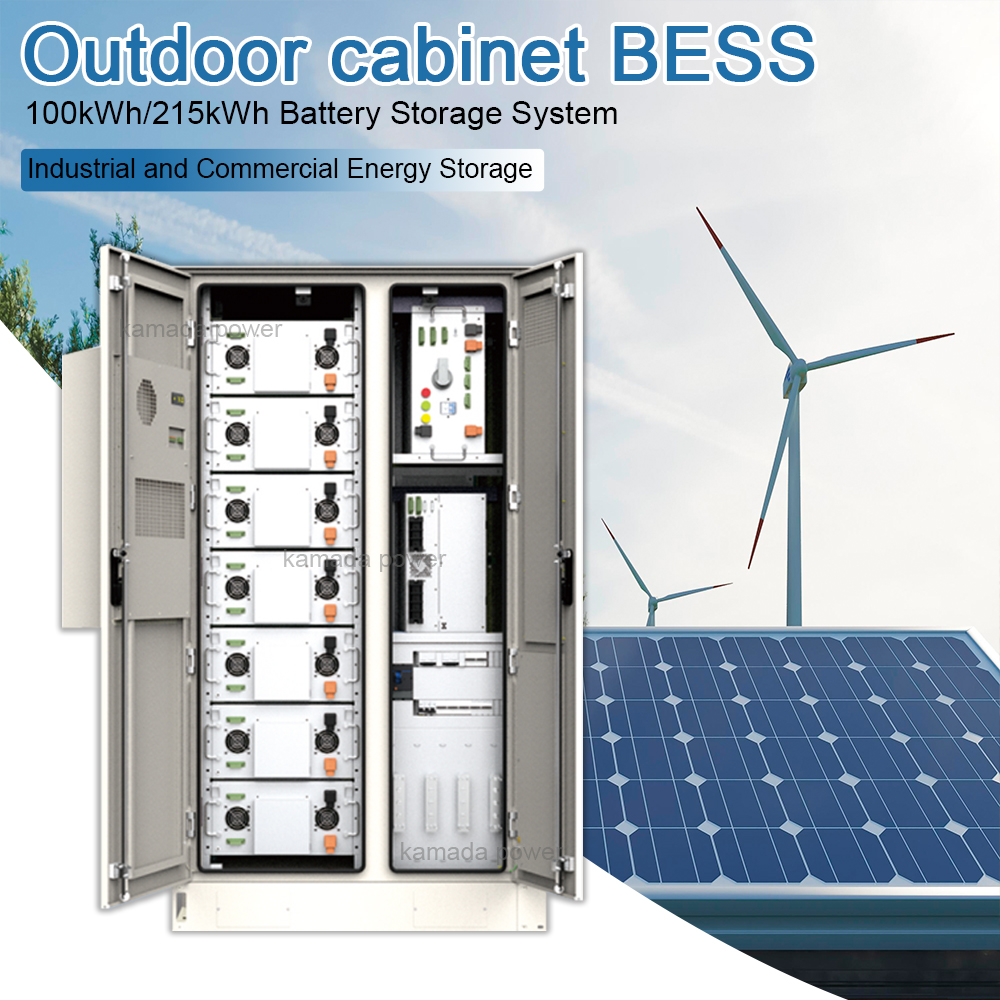

Kamada Power 100kwh Battery Energy Storage Systems

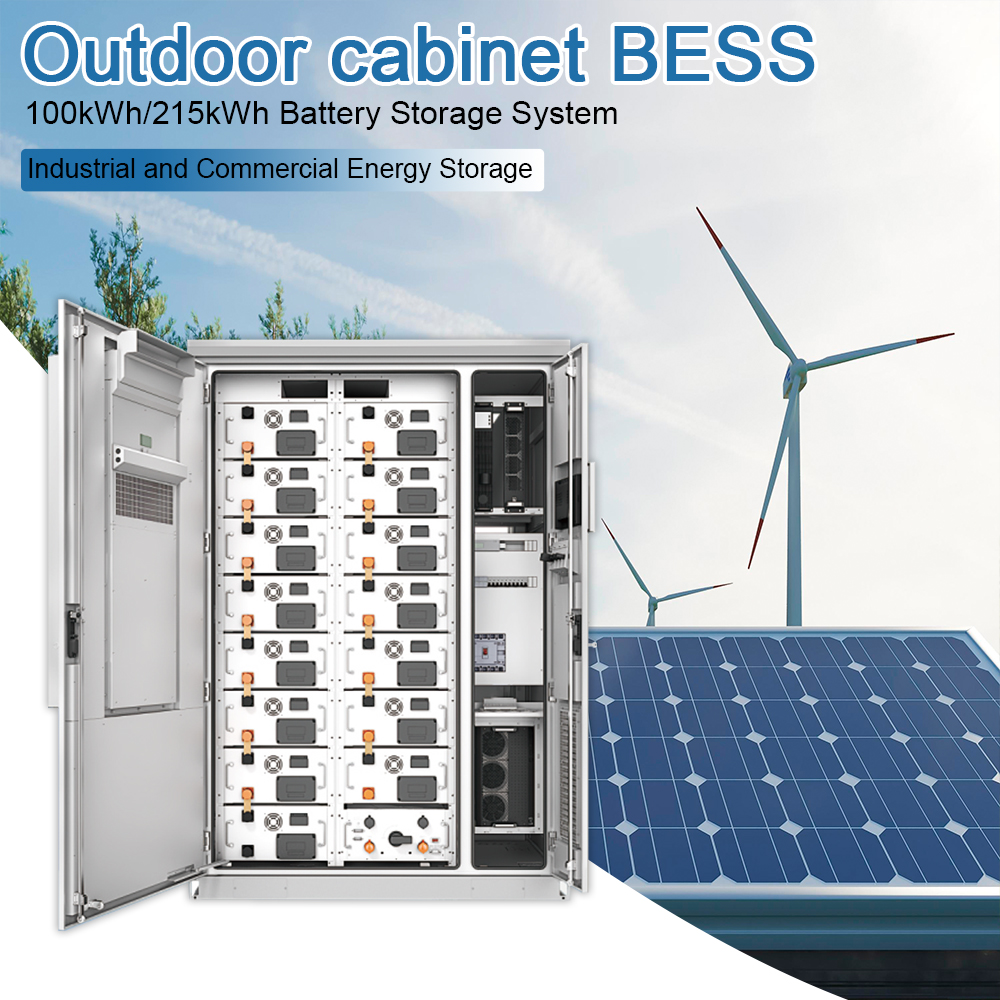

Kamada Power 215kwh Battery Energy Storage Systems

So, What Exactly IS an Industrial Battery System? (And How Does It Work?)

Think of an industrial battery system as a large-scale, intelligent power source for your facility. It captures electricity from the grid or on-site renewables (like solar), then releases that power precisely when it’s most valuable.

A complete system isn’t just the batteries. It also includes an inverter for AC/DC power conversion and a vital Battery Management System (BMS). The BMS is responsible for safety, performance, and the overall longevity of the asset.

The functionality delivers a few key applications:

- Backup Power & UPS: In a grid outage, the system takes over instantly. This protects sensitive machinery and avoids the high costs of a full production restart.

- Peak Shaving: The battery discharges during your high-use periods, effectively “shaving” the peak from your utility bill and cutting expensive demand charges.

- Energy Arbitrage: It charges at night when electricity is cheap and discharges in the afternoon when it’s expensive. This directly reduces your electricity spend.

The 3 Core Reasons Businesses are Investing in Battery Storage

Why are businesses investing in battery storage? Our work with industrial clients shows the decision usually addresses one of three key issues.

- Operational Resilience: In manufacturing, data centers, or cold storage, even a brief power loss is a major disruption. A BESS delivers uninterruptible power, acting as the best insurance policy against an unreliable grid.

- Cost Control & Predictable ROI: Demand charges can make up 30-70% of a commercial electricity bill. Using a battery to manage peak demand gives you direct control over that expense, which makes calculating a return on investment straightforward.

- Strategic Energy Management: Companies face real pressure to hit ESG targets. A BESS allows them to store and use their own renewable energy instead of selling it back to the grid for a low price. This drives both energy independence and a greener footprint.

Tech Talk, Simplified: Key Terms You MUST Know

When you review spec sheets, the jargon can be a barrier. Focus on these terms:

- Capacity (kWh – Kilowatt-hours): This is the system’s energy reserve. It tells you how long it can run your equipment. A 500 kWh system could run servers for eight hours or an assembly line for one. It’s all about duration.

- Power Rating (kW – Kilowatts): This is the instantaneous output. It defines how much equipment you can power at once. High capacity is useless if the power rating is too low to start your large motors.

- Battery Chemistry: A major topic of discussion. For years, Lithium Iron Phosphate (LiFePO4) has been the default choice, valued for its safety and long cycle life. Now, sodium-ion battery packs are emerging as a serious contender for stationary storage.

| Feature | Lithium Iron Phosphate (LiFePO4) | Sodium-Ion (Na-ion) |

|---|

| Best For | Proven reliability, high cycle life | Cost-sensitive, wide temperature applications |

| Raw Materials | Lithium, phosphate (supply chain concerns) | Sodium (abundant, lower cost) |

| Extreme Temp Performance | Good, but requires thermal management | Excellent, operates well in cold/hot |

| Maturity | Industry Standard | Emerging, rapidly improving |

Expert Tip: We get this question a lot: sodium-ion battery or LiFePO4? Here’s our current take: if you need maximum energy density and a technology with a long, proven track record, LiFePO4 is the conservative choice. If your project has extreme temperature swings or you’re concerned about lithium price volatility, sodium-ion deserves a hard look.

Your 5-Step Action Plan to Get Started

Here is the structured approach we use with our clients to move from theory to practice.

- Step 1: Conduct an Energy Audit. You need data before you do anything else. Pull your utility bills (get 15-minute interval data if possible) to find your peak demand, usage habits, and what downtime actually costs you.

- Step 2: Define Your Technical Requirements. What problem are you solving? Backup, peak shaving, or both? List the critical loads that must run during an outage. This will determine the required capacity (kWh) and power (kW).

- Step 3: Vet System Integrators, Not Just Brands. Great hardware will fail if the system integration is poor. Find a partner with proven experience in your specific application, whether that’s manufacturing or marine power.

- Step 4: Request Detailed Proposals (RFPs). Don’t just look at the price. A solid RFP demands performance guarantees, a full Total Cost of Ownership (TCO) model, and specifics on the warranty and service level agreements (SLAs).

- Step 5: Focus on Performance Guarantees. A credible partner will contractually guarantee the system’s performance. The contract must be clear about expected savings or uptime, and what happens if those metrics aren’t met.

Conclusion

Ultimately, an industrial battery system is about gaining control over your facility’s power. Control over volatile costs, control over grid disruptions, and control over your energy strategy. It’s a major investment, but it converts energy from a liability into a managed asset.

You now have the framework to ask the right questions. The first step is always the same: understand your own energy data.

Ready to analyze your energy profile? Contact us. Schedule a no-obligation system assessment with our engineers to model the ROI for a system designed for your facility.

FAQ

What is the realistic cycle life of an industrial LiFePO4 battery?

A quality system is typically warrantied for 10-15 years or 6,000 to 10,000 charge cycles. The longevity depends heavily on the quality of the BMS and the thermal management system protecting the cells.

Can we integrate a battery system with our existing backup generators?

Absolutely. It’s a common and highly effective setup. The battery handles the immediate load during an outage, saving the generator for extended blackouts. This cuts generator run-time, fuel burn, and maintenance.

What if our energy needs grow in the future?

Modularity is a key feature to ask about. Many modern BESS are designed like building blocks. You can install a system for today’s needs and easily expand capacity as your operation grows.