How Do I Install a Behind-Seat Ohut litium-akku in an AU Dual Cab Without Rework? (10 Traps). If you’ve ever supplied a “clean behind-seat slimline lithium kit” into a dual cab build, you’ve seen it: day one looks OEM and the tub stays free—day seven you’re getting the call because the seat won’t latch, the DC-DC is cooking, or the inverter chirps low-voltage when the kettle or coffee machine kicks in, and everyone blames the battery. The truth is most failures are packaging, voltage drop, and charging design—not Ah.

Kamada Power 12v 200Ah Slimline litiumakku

Why Behind-Seat Slimline Lithium Is So Popular in AU Dual Cabs

What behind-seat solves

Behind-seat slimline installs are popular because they solve very real constraints:

- Space efficiency: a slimline LiFePO₄ battery fits where a traditional “box” won’t.

- Theft resistance and aesthetics: inside the cabin is harder to access and looks tidy.

- Tub usability: tradies and fleet operators keep the tub open for payload.

- Cleaner harnessing: less exposure to weather and dust compared to external mounts.

But it also creates predictable engineering headaches:

- Tighter airflow: everything runs warmer behind trim and carpet.

- Moving seat mechanisms: rails, hinges, latch points—things that rub or pinch cables over time.

- Longer cable runs: inverter and distribution often end up farther from the battery.

- Higher safety expectations: an in-cabin energy storage system must be mounted like it matters—because it does.

From our experience working with industrial and fleet clients, the behind-seat approach usually wins on packaging and theft risk—but it only stays “clean” if the electrical design is treated like a system, not a collection of parts.

When behind-seat is the wrong choice

There are builds where behind-seat is simply the wrong architecture, even if the battery “fits”:

- High continuous inverter loads (e.g., heavy appliances run daily, long duration)

- Zero-airflow cavities where DC-DC chargers and inverters will thermally derate

- No safe mounting points (anything that relies on trim plastics is a red flag)

- Heavy seat pressure zones where the seat back physically loads the battery or wiring

In those cases, you’re often better off with a quick alternative: a canopy side panel, a sealed tub boxtai undertray solution—each with its own tradeoffs in exposure, serviceability, and cable length.

Behind-seat installs typically reduce theft risk and preserve cargo space, but they can increase labor time and commissioning requirements. Canopy or tub-box installs often simplify airflow and service access, but they can increase exposure and require better environmental sealing (dust, water ingress). In procurement terms: choose the option that minimizes total cost of ownership—not just component cost.

The Fitment Triangle: Size + Seat Motion + Service Access

Trap #1: Measuring only thickness, not the full envelope

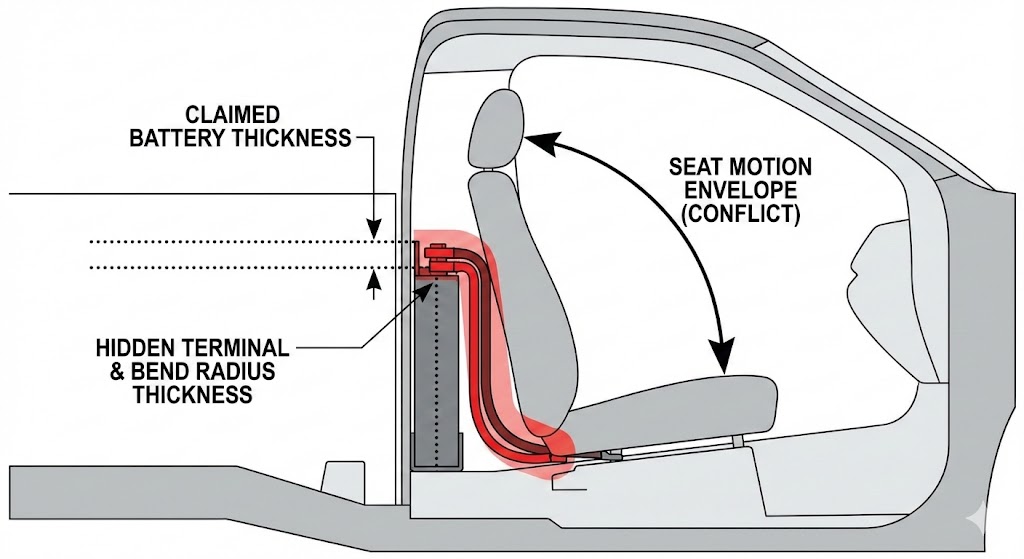

“Battery thickness” is the number everyone quotes. It’s also the number that causes tear-downs.

Behind-seat cavities aren’t rectangles. You have seat-back contours, trim protrusions, carpet bulges, and sometimes surprising geometry changes from bottom to top. The difference between measured gap ja usable gap is usually where the install goes wrong.

Prevention: measure the cavity in three vertical zones—low/mid/high—and include the full seat-motion envelope. Then add clearance for terminals and cable exits. If you can’t close the seat smoothly with your hand, it will not survive a year of real driving.

As shown in the figure, measuring only the thickness of the battery body is the primary cause of rework. Sufficient “envelope space” must be provided for terminal protrusions, the minimum bending radius of thick cables, and the movement path of the seat after compression. If your seat requires force to snap into place, your cables are being squeezed.

Trap #2: Forgetting terminals and cable bend radius

A slimline battery can fit perfectly… until you add terminals and cabling.

Terminals add “hidden thickness.” So do fuse holders, busbars, and the bend radius of heavy conductors. If your DC path includes 2/0 cable (or equivalent metric cross-section), it doesn’t like making sharp turns behind trim. It will push back. Literally.

Practical rule: plan a dedicated cable lane and strain relief. If the cable is forced into a tight kink, you’ll see higher resistance, heat, and eventual loosening at the lug.

Trap #3: No service access plan

If a tech can’t reach fuses, a DC-DC reset, or an isolation switch without removing the seat, you’ve baked rework into the design.

Use the two-minute rule: can you isolate, fuse-check, and reset without seat removal? If not, it’s not a “clean” install—it’s a hidden future labor bill.

Mounting & Safety: The #1 Reputation Risk for In-Cabin Batteries

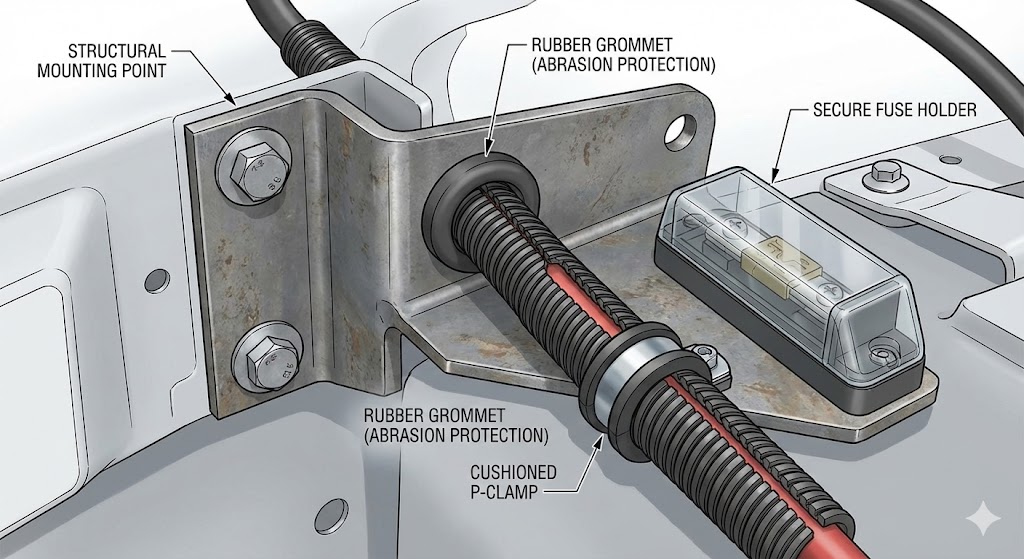

Trap #4: Mounting that isn’t crash-safe

A lithium battery is dense. In a cabin, that matters.

A poorly mounted battery becomes a projectile risk in a collision. “Crash-safe” means the mounting path transfers load into structural points using appropriate brackets, backing plates, and fasteners—not trim panels. It also means the battery can’t shift, chafe wiring, or deform surrounding parts under vibration.

For B2B buyers, this is more than safety—it’s liability management. A clean mechanical design reduces disputes, insurance questions, and reputational damage.

As shown in the diagram, this installation detail is designed to withstand the rigors of Australia’s outback terrain and potential impacts. Note the structural metal mounting points, rubber cable protection sleeves to prevent wear, and standardized cable clamps. These seemingly minor details are crucial for preventing electrical fires and ensuring long-term reliability.

Trap #5: Ignoring edge protection and abrasion paths

Seat rails, latch points, hinge arcs, and sharp sheet metal edges are cable killers. The failure mode is sneaky: the system works for weeks, then an intermittent short or nuisance fuse blows appears “randomly.”

Use proper grommets, split conduit, P-clamps, and strain relief. Treat every pass-through as a wear point. If a cable can move, it will.

Installer proof pack

Professional installers reduce arguments by documenting:

- Mount points and bracketry (photos)

- Fuse placement and ratings (label + photo)

- Cable protection at pass-through points (photo)

- Commissioning notes: voltage readings + observed charge behavior

Procurement teams love this because it becomes acceptance criteria. Engineers love it because it turns “I think it’s fine” into “we measured it.”

DC-DC Charging: Where Behind-Seat Builds Win or Fail

Trap #6: “Lithium upgrade” without a charging design

Modern vehicles often use smart alternators (variable voltage, ECU-managed). A simple isolator strategy that worked for AGM batteries can underperform—or behave inconsistently—with LiFePO₄.

This is why a DC-DC charger is often the correct path for stable lithium charging: it manages charge profile (bulk/absorption/float), limits current appropriately, and can handle alternator behavior better than a “dumb” connection.

Real-world use case #1: fleet dual cabs with short daily routes. Without DC-DC, the battery never reaches full state of charge, and warranty claims start showing up as “battery capacity loss” when the real issue is chronic undercharge.

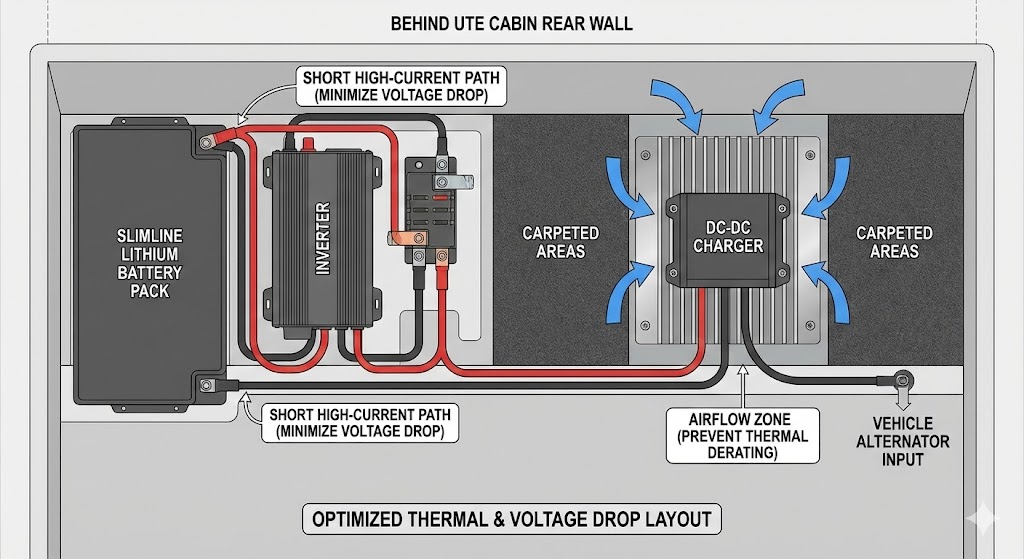

Trap #7: DC-DC placement that overheats and derates

Behind-seat cavities are warm. DC-DC chargers create heat. Combine the two and you get thermal derating.

Heat sources include enclosed cavities, carpet/trim insulation, and low airflow. Many chargers protect themselves by reducing output—so the customer says “it charges sometimes.”

Prevention: build airflow into the design. Leave a real air gap around the charger, mount it to a surface that can sink some heat, and avoid stacking hot components together.

As shown in the diagram,An optimal layout is a balancing act: positioning the inverter close to the battery to meet high-current demands (minimizing voltage drop), while “isolating” the DC-DC charger in an airflow-accessible area and mounting it on a heat sink substrate to prevent reduced charging efficiency due to overheating.

Trap #8: Putting DC-DC in the wrong electrical location

There’s a tradeoff between putting the charger near the crank battery (shorter alternator feed) and near the house battery (shorter charger-to-battery run). Packaging often forces decisions.

Tässä on avain: voltage drop shows up where you least want it—between the charger and the battery. A charger may “think” it’s outputting the right voltage, but if the battery terminals see less due to cable loss, you get slow charging and incomplete absorption.

Commissioning step: measure at battery terminals during charge, not just at the charger.

Voltage Drop & Cable Rules

Trap #9: Undersized cable on 12V high-current paths

12V systems are unforgiving because current gets big fast. And losses scale roughly with I²R—double the current and resistive heating can jump about fourfold.

Common symptoms:

- Inverter low-voltage alarms under load

- DC-DC throttling

- Warm lugs/terminals (a quiet but serious warning)

Real-world use case #2: mobile service vehicles running tools, a small inverter, and refrigeration. The pack is fine, but marginal cable and poor crimping create voltage sag and nuisance shutoffs.

A simple voltage-drop workflow

- Identify the max current path (inverter feed or DC-DC output)

- Measure one-way cable length (real routing, not straight-line)

- Choose cable size based on acceptable drop + heat margin

- Verify with a load test and record results

Where to measure

- Battery terminals vs inverter terminals under load

- Charger output vs battery terminals during charge

- Interpret results: “if drop is here, fix this”

Protection & Distribution: Fuses, Isolation, and “Nuisance Trip” Prevention

Trap #10: Fuse placement mistakes (unsafe segments or constant trips)

The core principle is simple: protect the cable, not the appliance. Place protection close to the source so you don’t leave long unfused segments. Coordinate branches so one fault doesn’t take down everything—or so the wrong fuse doesn’t blow first.

For behind-seat builds, this often means separating high-current inverter feeds from lower-current DC outlets and refrigeration circuits.

Isolation strategy installers forget until the call-back

Serviceability matters. Put the isolator where it can be reached. Label it. If a customer can’t safely shut the system down, they’ll do something creative—and you’ll hear about it later.

Grounding strategy that doesn’t create ghosts

Chassis return can work, but it must be treated as an engineered conductor, not an assumption. In many high-current or noise-sensitive systems, a dedicated negative return avoids unpredictable voltage drops.

Testing approach: verify drop on the negative side too. Bad grounds create some of the most time-wasting faults.

The Shop-Pro “One-and-Done” Install Process

Step-by-step installation workflow

- Fitment template + 3-point measurement

- Mechanical mounting + cable lane planning

- Electrical layout: DC-DC, fusing, distribution

- Cable routing + abrasion protection

- Commissioning tests + documentation

- Customer handover: what to check after first week

Real-world use case #3: overland / expedition builds that add Starlink/comms, fridge/freezer, lighting, and occasional high-power loads. When the build includes commissioning records, field troubleshooting is dramatically faster—and returns drop.

Commissioning tests that reduce warranty arguments

- Charging test: alternator → DC-DC → battery terminal voltage

- Inverter test: load test + terminal voltage drop

- Thermal check: DC-DC and lugs after run time

Troubleshooting: Fast Diagnosis for the Most Common Call-Back Complaints

Inverter beeps low voltage

Check voltage at inverter terminals and compare it to battery terminals under the same load. If the inverter sees significantly lower voltage, you likely have cable loss, loose lugs, undersized conductors, or a weak ground path.

It charges while driving, but never reaches full

Check DC-DC settings and measure battery terminal voltage during charge. Common causes include DC-DC derating from heat, alternator input voltage sag, or a charge profile mismatch (wrong lithium settings, incorrect temperature sensing, etc.).

Battery cuts out under load

Check BMS protections: current limit, low-voltage cutoff, and temperature. Then identify whether it’s an overcurrent event (instant cut under load) or a sag-to-LVC scenario (voltage collapses first). The fix is different.

Päätelmä

A behind-the-seat slimline install isn’t about finding the thinnest battery—it’s about engineering a complete 12V ecosystem that can handle vehicle dynamics, heat, and the unforgiving physics of DC. When you move past dimensions and prioritize crash-safe mounting, purposeful airflow, and voltage-drop-proof cabling, you stop creating “battery problems” and start delivering OEM-grade power that survives the Australian outback without warranty headaches. Ota yhteyttä osoitteessa customized slimline lihtium battery ratkaisuja.

FAQ

What thickness slimline battery fits behind a dual cab rear seat?

It depends on the vehicle and the seat envelope—not just a single thickness number. Measure the cavity in multiple zones (low/mid/high), include seat motion, and account for terminals and cable bend radius. That “hidden thickness” is what usually triggers rework.

Is it safe to mount a lithium battery behind the rear seat?

It can be safe if the mounting is crash-safe: structural attachment points, appropriate brackets and backing plates, abrasion protection, and properly protected cabling. In-cabin installs raise the bar on mechanical integrity and documentation.

Do I need a DC-DC charger for a lithium battery in a modern ute?

Often, yes—especially with smart alternators. A DC-DC charger provides a controlled lithium charge profile and consistent output when alternator voltage varies. It’s commonly the difference between “works on day one” and “never quite charges right.”

Where should the DC-DC charger go in a behind-seat install?

Ideally where it has airflow and where voltage drop between the charger and the battery is minimized. Many successful builds place the DC-DC close to the house battery, then size the alternator feed accordingly. Always validate by measuring at the battery terminals during charge.