Difference Between UPS and BESS. You’re a procurement officer, and a plant manager forwards a “simple” request: “We need battery backup.” No scope, no one-line, no load list—just that sentence, and the quiet reality that the next outage becomes your problem. The catch is that “battery backup” can mean two very different systems: a UPS for instant continuity + power conditioning on critical loads (milliseconds transfer, seconds–minutes runtime), a BESS for energy storage + facility/grid control (minutes–hours for peak shaving, solar shifting, microgrids), and in many industrial sites the most practical answer is UPS + BESS—UPS rides through, BESS carries the hours and the savings.

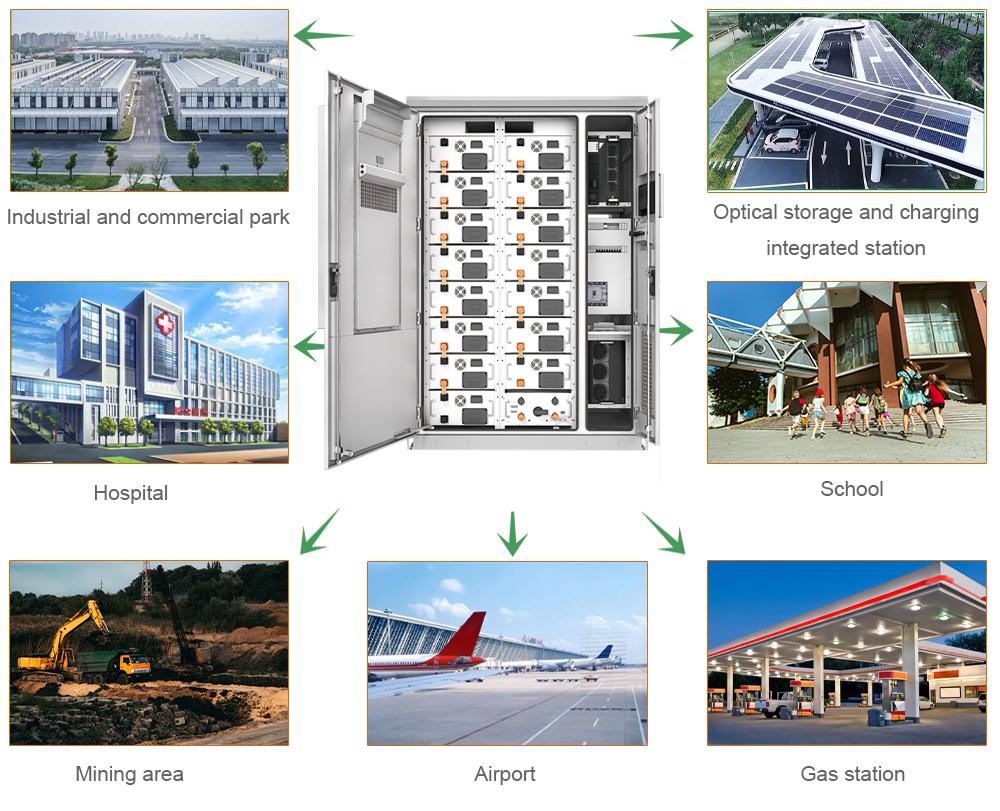

Kamada Power 215kWh BESS

What is a UPS?

A UPS (Uninterruptible Power Supply) exists for one job: keep a critical load bus alive with clean, continuous power when the utility hiccups—or disappears.

What it actually does, in plain English:

- Voltage/frequency regulation: It conditions power so sensitive loads don’t get “dirty” voltage, sags, swells, or frequency wobble.

- Ride-through: It bridges the gap between normal utility power and “something else” (generator startup, transfer, or controlled shutdown).

- Bypass modes: Most serious UPS systems include static bypass and maintenance bypass paths so you can service the unit without taking the load down.

Typical design language you’ll hear from UPS vendors and engineers:

- kVA/kW, power factor, harmonics, crest factor

- Redundancy: N+1, 2N, distributed redundancy

- Static switch / STS, maintenance bypass, battery autonomy time

Typical runtime: seconds to minutes. Yes, you can spec longer runtime, but that’s not the usual mission. In data centers, for example, the UPS often exists to bridge and stabilize—then generators and/or larger energy systems take over.

What is a BESS?

A BESS (Battery Energy Storage System) is a different animal. Its primary mission is energy shifting and dispatchable power at the facility or grid level—not just keeping one rack alive for a few minutes.

Core subsystems you’re buying in a true BESS:

- Battery racks / containers (often lithium-ion, sometimes LFP/NMC, or other chemistries depending on use case)

- BMS (Battery Management System): cell monitoring, protection, balancing, limits

- PCS (Power Conversion System): the bidirectional inverter that interfaces batteries to the AC bus

- EMS / controller: dispatch logic, scheduling, demand response, microgrid coordination

- Protection + switchgear: breakers, relays, anti-islanding, grounding strategy

- Thermal management: HVAC, liquid cooling, ventilation—because power electronics and batteries don’t like heat

Typical design language for BESS looks like:

- kW + kWh, duty cycle, SOC window, throughput (MWh/year)

- Interconnection and controls: PCC, grid code compliance, islanding strategy

- Value stack: peak shaving, TOU arbitrage, demand charge management, resilience

Typical runtime: minutes to hours. Sometimes longer, but that’s usually a different architecture conversation (and sometimes a different technology).

UPS vs BESS — The 12 Differences That Matter in Real Projects

| # | What matters in projects | UPS (what it’s built for) | BESS (what it’s built for) |

|---|

| 1 | Primary mission | Power continuity + power quality for critical loads | Energy management + dispatchable power at facility/grid level |

| 2 | Transfer time / ride-through | Near-zero interruption (milliseconds) | Topology-dependent; “seamless” needs microgrid controls + switchgear |

| 3 | Runtime profile | Seconds–minutes (bridge events, orderly shutdown, generator start) | Minutes–hours (backup + peak shaving + energy shifting) |

| 4 | Control philosophy | Tight load regulation (voltage/frequency quality) | Grid-interactive PCS + EMS dispatch (multiple operating modes) |

| 5 | Electrical placement | Downstream on a critical bus | Facility bus / microgrid node / PCC interconnection point |

| 6 | Islanding & switching | Static switch / STS / ATS for critical bus continuity | Microgrid controller + protection + switchgear + islanding logic |

| 7 | Redundancy model | 2N / N+1 architectures, bypass paths, uptime-focused | Availability via strings/modules + controls redundancy + protection coordination |

| 8 | Standards & compliance | UPS standards + power quality expectations (e.g., UL/IEC) | Energy storage safety + interconnection (e.g., UL 9540/NFPA 855/IEEE 1547—project dependent) |

| 9 | Economics | You “get paid” by avoiding downtime and protecting critical equipment | You “get paid” via bill savings + incentives + grid services + resilience |

| 10 | Maintenance profile | Battery testing, bypass checks, capacitor aging, periodic load tests | HVAC, firmware/EMS alarms, battery health analytics, warranty throughput limits |

| 11 | Typical failure modes | Overload → bypass transfer, battery string issues, static switch behavior | Protection trips, SOC mismanagement, thermal derating, inverter limits |

| 12 | Commissioning & testing | Load bank ride-through, transfer behavior, bypass operation | Dispatch modes, islanding tests, protection settings, black-start strategy (if applicable) |

A quick buyer-focused comparison: If your biggest fear is “the line stops for 30 seconds and costs us six figures”, you’re thinking UPS territory. If your biggest pain is “our demand charges are brutal and outages last hours”, you’re thinking BESS territory. And if you have both problems… welcome to the club. That’s why layered architectures are common.

Can a BESS Replace a UPS?

When the answer is “No” (Most critical-load cases)

If you have zero/near-zero interruption requirements, a BESS alone usually isn’t the right tool.

Common “no” cases:

- Sensitive IT loads (server rooms, networking cores) where even a short transfer causes reboot, corruption, or cascading faults

- Critical controls that can’t drop: high-speed automation controllers, certain process controls, safety systems

- Tight power-quality tolerances: voltage/frequency regulation requirements that are more UPS-like than grid-interactive

From our experience working with industrial clients, the “we’ll just use a big battery” idea often dies during the first serious discussion about transfer time, switchgear, and who owns the control logic when the grid disappears.

When the answer can be “Yes” (With conditions)

A BESS can replace a UPS if:

- The loads tolerate a brief transfer (or can ride through with local capacitance/flywheel/controls)

- You design islanding + fast switching + control strategy properly

- You accept a different reliability model: BESS tends to be about availability and dispatch, not “no-drop continuity” by default

In practice, this is more common in facilities where the “critical” loads are things like pumps, conveyors, HVAC, or processes that can restart without major consequence—versus a data center core.

The most common architecture: UPS + BESS (Layered)

This layered approach is popular for a reason:

- UPS on the critical load bus (instant continuity + conditioning)

- BESS on the facility bus / microgrid node (hours of backup + cost savings + dispatch)

- Optional generator coordination: start, ramp, handoff

Which One Should You Choose?

Decision Tree

- If no reboot allowed → UPS

- If you want peak shaving / TOU arbitrage / solar self-consumption → BESS

- If you need minutes-to-hours resilience → BESS (or generator + BESS)

- If you need instant ride-through + hours backup → UPS + BESS

Quick Sizing Guidance (Practical, Low-Math)

UPS sizing (think power quality + continuity):

- Start with kW/kVA and power factor

- Add growth margin (loads never stay still)

- Define autonomy time: “How long must it ride through?”

- Decide redundancy level: N+1 vs 2N

- Validate ride-through and transfer behavior with your real loads

BESS sizing (think power + energy + duty cycle):

- kW: how much power you need to deliver (including surge/step loads if relevant)

- kWh: how long you need to sustain it (outage duration, peak window)

- SOC window: are you operating 20–80% or tighter?

- Demand charges and TOU windows: when does storage create real value?

- Interconnection constraints at the PCC (utility rules matter)

Examples

Data Center / Server Room

- UPS required for continuity and conditioning

- BESS optional for demand management, resilience, or to reduce generator runtime

- Common architecture: UPS on critical bus + BESS upstream at facility level

Factory with Demand Charges + Brief Outages

- BESS is often a strong ROI play for demand charge reduction and TOU arbitrage

- A small UPS may still be needed for PLCs, controls, and networking that can’t drop

- This is a classic “mixed criticality” site—procurement needs a load map, not just a power number

Hospital Imaging / Sensitive Equipment

- UPS for clean power and continuity on sensitive imaging/IT segments

- BESS can support facility resilience, but compliance, switching topology, and operational protocols are non-negotiable

- The question isn’t “can it work?”—it’s “can it be commissioned, tested, and operated safely?”

Solar + Microgrid / Remote Site

- BESS is central: dispatch, solar shifting, islanding, generator coordination

- UPS only for “must-not-drop” controls/IT that cannot tolerate transfer events

Common Mistakes (And How to Avoid Them)

- Confusing kW vs kWh (and why it breaks both UPS and BESS designs)

- Assuming “big battery = UPS” (transfer time and controls are the real trap)

- Forgetting switchgear, protection, grounding implications

- Underspec’ing thermal management / ignoring derating

- Ignoring BESS warranty throughput / cycle limits (your dispatch profile matters)

- Treating “islanding” as a checkbox instead of a control + switchgear design problem

Conclusion

UPS and BESS solve different problems, even if they both happen to contain batteries: a UPS is about instant continuity and power quality on a critical bus, while a BESS is about energy + control—bill savings, dispatch, and longer-duration backup at the facility or grid level—and in many real plants the cleanest answer is a properly layered UPS + BESS. Need a fast second opinion? Send four items—critical load list (kW/kVA), required ride-through time, desired backup hours, and site voltage (208/480/…)—and I’ll sanity-check the architecture and the biggest sizing assumptions, plus flag the common “goes sideways” points before they get expensive. Contact us today.