How to Prepare Golf Cart Batteries for Winter. When spring arrives, a fleet of dead utility vehicles isn’t just an inconvenience; it’s a sudden, unplanned capital expense to replace entire battery packs. This silent failure costs businesses thousands in hardware and lost productivity each year. The culprit is always winter.

Based on our experience with industrial clients, a few hours of preventative maintenance in the fall prevents these costly, fleet-wide failures. Weather conditions are a key factor—a Minnesota resort has different challenges than a Florida campus—as are your specific storage locations and building insulation.

These principles apply directly to the lead-acid and lithium battery packs in all your electric industrial equipment, from forklifts to aerial work platforms. We’ll walk you through the exact process to prepare your batteries for winter, protecting your assets and budget.

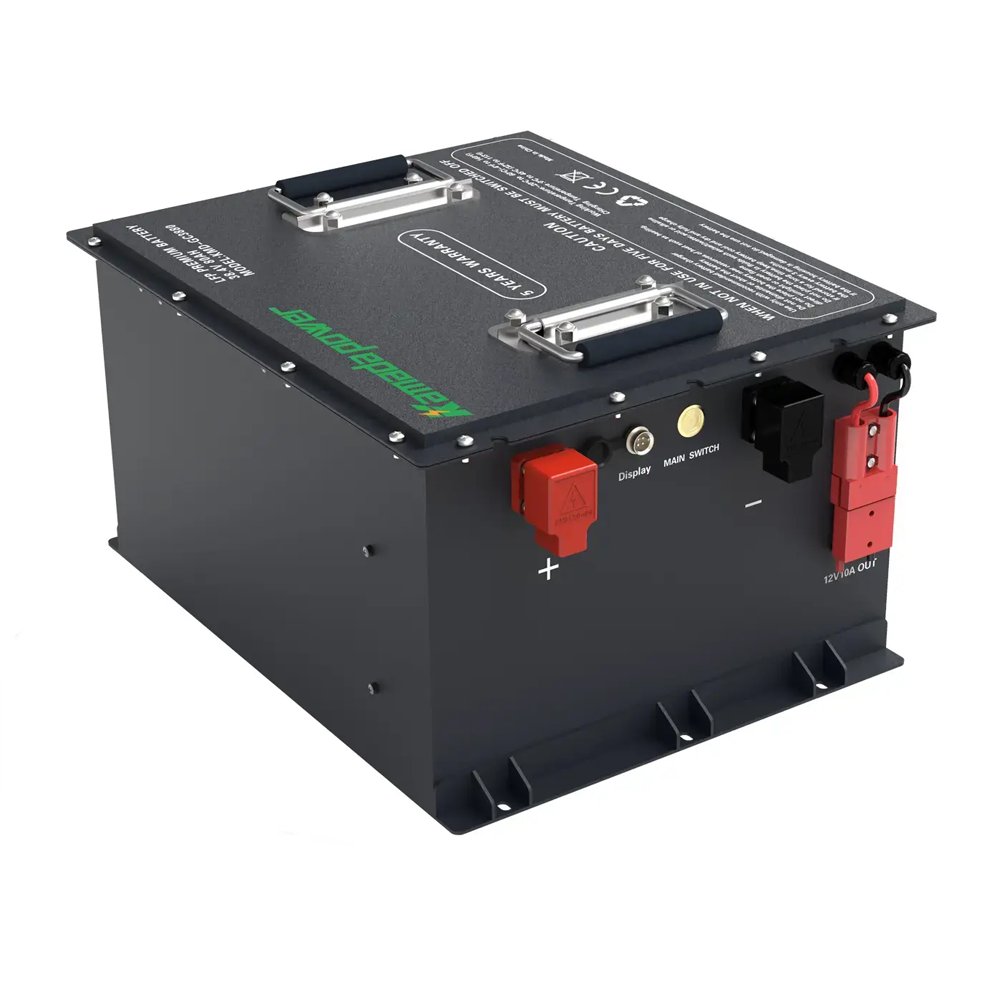

Kamada Power 48V 100Ah Lithium Golf Cart Battery

Why Winterizing Your Batteries is Non-Negotiable

Ignoring battery prep before a long shutdown isn’t just risky—it’s a guaranteed way you’ll shorten the operational lifespan of your equipment. Here’s the science behind why this is such a big deal.

- Sulfation: The Silent Killer: Think of sulfation as arthritis for lead-acid batteries. When a battery just sits there in a discharged state, tiny lead sulfate crystals start to form on the plates. At first, they’re soft, and a normal charge cycle can break them down. But let them sit over a long, inactive winter, and these crystals harden and grow, permanently choking the battery’s capacity. For a forklift operator, that means shorter run times and more charging, which ultimately kills the battery cycle life.

- The Danger of Freezing: Here’s a critical fact: a fully charged battery is practically freeze-proof, with its electrolyte freezing somewhere around -70°F (-57°C). In a discharged state, however, it’s a different story. The electrolyte is mostly just water with a bit of acid, and we all know what happens to water at 32°F (0°C). It freezes, it expands, and it can easily crack the battery case, buckle the plates, and cause irreversible damage. Winter temperatures in northern states or Europe can easily dip below safe levels for discharged batteries, making this step critical.

- Self-Discharge: Every battery naturally loses a bit of charge over time, it’s just a fact of life. While cold temperatures actually slow this process down, a three-to-five-month storage period is more than enough for a battery to discharge itself into the danger zone. Even mild climates aren’t exempt: indoor storage in unheated garages or sheds can still lead to gradual discharge and unexpected dead batteries.

Alright, before anyone on your team even thinks about touching a terminal, we need to talk about safety. Any professional maintenance bay considers this standard operating procedure, and for good reason.

Your Safety Checklist (Non-negotiable!):

- Work in a well-ventilated area to disperse hydrogen gas that batteries release during charging.

- Always wear safety glasses and chemical-resistant gloves.

- Enforce a strict no-smoking, no-sparks, no-open-flames policy near the battery area.

- Keep a neutralizer like baking soda and water handy for any potential acid spills.

Essential Tools & Supplies:

- Socket wrench set

- A dedicated battery terminal cleaner or wire brush

- Distilled water (for serviceable flooded lead-acid batteries only)

- Baking soda and water solution

- Lint-free cloths

- A quality automatic battery maintainer. And let’s get one thing straight: a maintainer is not the same as a trickle charger. A simple trickle charger pushes a constant current that can overcharge and cook a battery over several months. A smart maintainer, on the other hand, monitors the voltage and only gives it a little juice when needed.

- A digital voltmeter (a must-have for pros)

The Step-by-Step Winterization Process

Here is the field-tested procedure we use to make sure our clients’ electric vehicle batteries survive the off-season, whether you’re in snowy Minnesota, rainy Seattle, or mild California.

Step 1: Clean the Batteries and Terminals

Corrosion and grime on top of a battery can create a small electrical path, causing a slow but steady discharge. A clean battery is a happy battery. Disconnect the main cables and use a baking soda paste to scrub the terminals until they are bright and shiny. Rinse carefully with a little water, making sure none gets into the battery cells, and dry everything thoroughly.

Step 2: Check and Top-Off Water Levels (Flooded Lead-Acid ONLY)

This one is only for folks running fleets with traditional flooded lead-acid batteries, but it’s vital. Important: Always check and top-off water levels after you fully charge the battery. Charging causes the electrolyte to expand, so filling a discharged battery can lead to an acid overflow mess. Open the vent caps and add distilled water only, just enough to cover the plates or reach that little indicator ring.

Step 3: Fully Charge the Battery Pack

I can’t stress this enough: this is the single most important step in the whole process. A full state of charge gives you maximum freeze protection and keeps sulfation at bay. Connect the equipment’s charger and let it run through a complete, uninterrupted cycle.

Step 4: The Storage Decision – Connect a Maintainer or Disconnect?

You have two solid options here, and it really just depends on whether you have power at your storage location.

- Option A (Recommended): Use a Battery Maintainer. This is the “set it and forget it” solution for professionals. It intelligently monitors the battery pack and keeps it perfectly topped off all winter without the risk of overcharging. Honestly, it’s the best way to ensure the battery is in peak condition come spring.

- Option B (Acceptable): Disconnect and Store. If you’re storing the equipment in a shed or warehouse without power, the next best thing is to fully charge the pack and then completely disconnect the main negative cable. This isolates the battery and slows the discharge way down. However, you can’t just walk away. Your maintenance plan should include having someone check the pack’s voltage monthly and recharge it fully if it drops significantly (say, below ~48V for a 48V system). This is particularly important in colder regions, where even slight voltage drops can lead to freezing or sulfation over long periods.

Expert Breakdown: Winterizing Different Battery Types

Now, the specific chemistry of your battery really dictates the game plan here. What works for lead-acid is the wrong move for lithium.

| Battery Type | Key Winterization Steps | Special Considerations |

|---|

| Flooded Lead-Acid | Clean, Charge Fully, Check Water (after charge), Use Maintainer. | The workhorse of many fleets. Freezing poses the biggest threat when this battery is discharged, and it requires the most hands-on care. Storage location temperature and insulation matter greatly. |

| AGM (Absorbent Glass Mat) | Clean, Charge Fully, Use Maintainer. | A sealed, maintenance-free version of lead-acid. You can skip the water check, but sulfation can still damage it if left discharged. Keep in a temperature-stable environment for best results. |

| Lithium (LiFePO4) | Charge to 50%-70% (NOT 100%), Turn off or disconnect. | Whatever you do, do not use a standard lead-acid maintainer on it. Storing LiFePO4 at a full 100% charge for months can stress the cells. Their incredibly low self-discharge rate means they’ll barely lose any power over the winter anyway. Ideal storage is indoors, away from freezing temperatures. |

Conclusion

At the end of the day, winter battery care boils down to three simple rules: keep them clean, keep them charged, and keep them maintained. Investing a little bit of time in the fall is a proactive measure that protects some very significant capital assets. It eliminates that costly surprise of dead batteries in the spring and makes sure your equipment is ready to roll when your operations demand it.

No matter your region—icy northern winters, wet Pacific Northwest, or mild southern climates—a proper winterization plan ensures your fleet is ready when you need it.

A solid maintenance plan is your first line of defense. The ultimate solution? A better battery. Contact us.We specialize in custom golf cart battery solutions designed to minimize winter maintenance and maximize year-round reliability. Whether you’re optimizing your current packs or ready to upgrade, contact our engineering team to explore your options.

FAQ

Can we just leave our fleet vehicles plugged into their regular chargers all winter?

That’s a great question, and the answer is… it depends. An older, timer-based charger can easily overcharge a battery, boiling off electrolyte and causing real damage. A modern, multi-stage “smart” charger is much better, but a dedicated maintainer is still the safest tool for the job, since it’s designed specifically for long-term storage.

What if one of my guys missed a few units in the warehouse during winterization?

If you find batteries that sat in a discharged state all winter, you should probably manage your expectations. They’ve likely suffered from heavy sulfation and may have permanent capacity loss. You can try a slow “recovery” or equalization charge, but there’s a good chance they’ll need to be replaced.

How do we properly bring the batteries back online in the spring?

The spring “wake-up” process is pretty straightforward. First, do a quick safety inspection. Reconnect any disconnected cables, making sure the connection is tight and clean. For your flooded lead-acid batteries, double-check the water levels. Then, give the entire pack a full, fresh charge before you put it back into service. It’s also a good time to check the tire pressure on the vehicle itself.