A big part of my job as a battery specialist involves talking with ops managers and procurement folks, and I find they’re almost always fighting the same fire. They’re trying to power something remote—maybe a telecom tower out in the desert, a series of monitoring stations up north, or a critical backup system miles from anywhere. It always boils down to the same needs: it has to be reliable, it must be safe, and the budget is what it is. For years, the choice was a compromise between old-school lead-acid and some type of lithium-ion. That isn’t the whole story anymore.

Having been in this industry for over two decades, I’ve seen my share of “game-changers.” Frankly, most don’t last. The progress happening right now in sodium-ion battery technology, though, feels different. It’s a legitimate shift in the landscape, and it’s something you should be looking at if you’re in charge of these kinds of tough projects.

The goal of this article is to cut through the marketing hype. We’ll get into the real-world pros and cons of Na-ion for stationary power, see how it stacks up against the competition, and give you what you need to decide if it’s the right call.

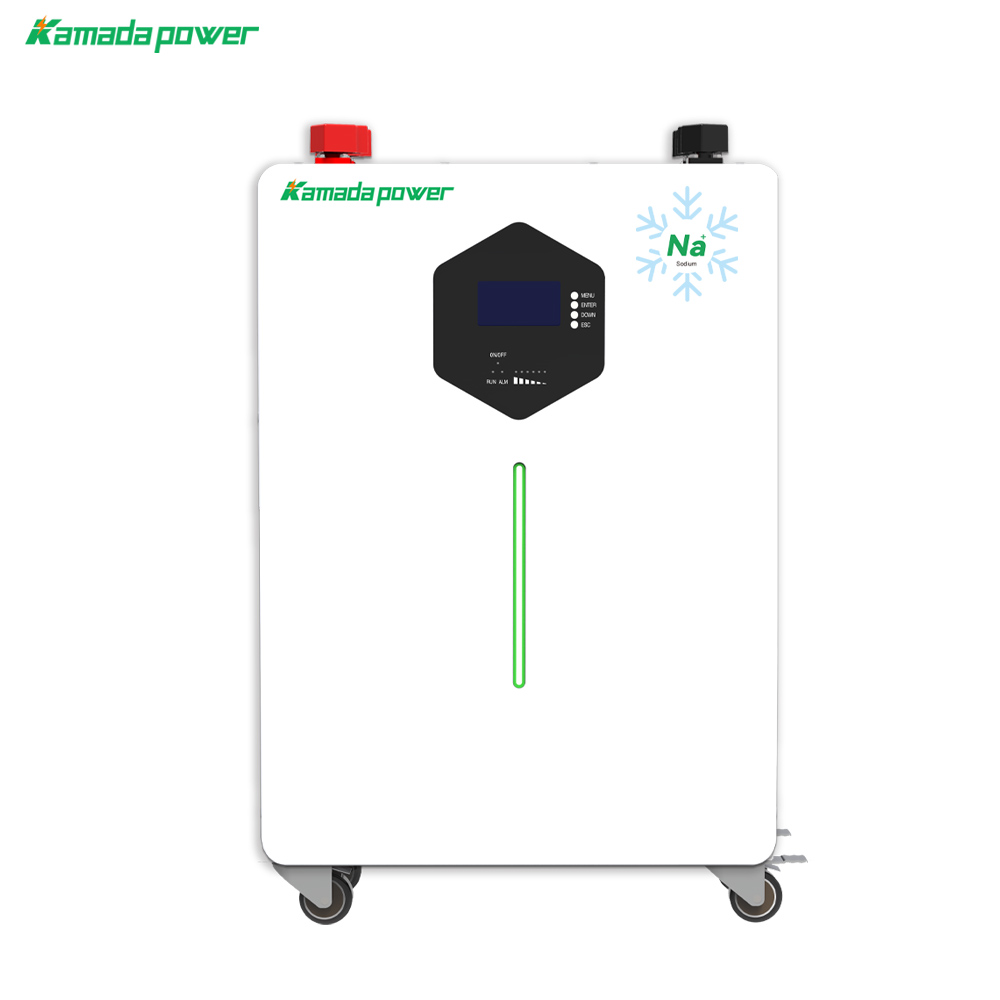

kamada power 10kwh home sodium ion battery

kamada power 12v 200ah sodium ion battery

What Exactly Are Sodium-Ion Batteries?

Alright, let’s get straight to it. The simplest way to think about a sodium-ion battery is as a close cousin to the lithium-ion tech we’re all so familiar with. They work on a similar principle of moving ions around to store and release power. The crucial difference—and the reason this is all happening now—is the core ingredient: it runs on sodium, which is derived from plain old salt, instead of lithium.

Why the sudden interest? The concept itself has been around for a long time, but it took recent breakthroughs in materials science and manufacturing to finally make it a realistic option at scale. Instead of being chained to a volatile supply chain for lithium and cobalt, Na-ion uses an element that’s incredibly abundant, all over the world. This move from a scarce material to a common one is a huge deal for both long-term cost stability and responsible sourcing.

The Pros: Why Sodium-Ion is a Strong Contender for Off-Grid Applications

In our experience, the tone of the conversation with industrial clients really changes when we get to these four points:

- Cost-Effectiveness: Let’s be honest, the bottom line runs the project. When you can engineer a battery that doesn’t need lithium, cobalt, or even copper (it uses aluminum for the current collectors), your material cost is just fundamentally lower. That means a lower upfront cost, yes, but the bigger deal is a much healthier Total Cost of Ownership (TCO) over the system’s life.

- Unmatched Safety & Stability: For any piece of equipment that’s going to be sitting out there unattended, safety is everything. The chemistry itself is simply less prone to thermal runaway than many lithium-ion types. The real operational win, though, is its tolerance for being fully discharged. You can literally take a Na-ion battery to zero volts for transport or storage without destroying the cells. That’s a massive logistical and safety advantage.

- Wide Operating Temperature Range: This is where Na-ion really feels like it was made for the job. These batteries hold up incredibly well across a huge temperature range, from a cold -20°C up to a hot 60°C (-4°F to 140°F). And importantly, they do this without needing a complex, power-draining thermal management system. For gear in the field, that means better reliability and one less thing to go wrong.

- Sustainability & Ethical Sourcing: More and more, a company’s ESG goals are a real factor in purchasing decisions. Sodium is one of the most common elements on earth. It just doesn’t come with the difficult ethical and geopolitical questions that follow cobalt and lithium around.

The Cons: Where Sodium-Ion Currently Falls Short

Now for the other side of the coin. No technology is perfect, and you have to be honest about the trade-offs. With sodium-ion, there are two main ones to keep in mind for now.

- Lower Energy Density: This is the big one. Pound for pound, a sodium-ion pack is heavier and bigger than a lithium-ion pack with the same energy capacity. If you’re dealing with tight space or weight limits—in something like a forklift or a marine vessel—this could easily make it a non-starter. But for stationary uses, like a commercial ESS in a standard container, a slightly larger footprint is often not a problem at all.

- Market Maturity & Availability: Let’s be realistic. The sodium-ion supply chain is still very new compared to the huge, established lithium-ion world. The simple fact is you have fewer manufacturers and off-the-shelf products to pick from today. While that’s changing fast, it’s a practical problem for any procurement team at this moment.

Sodium-Ion vs. Lithium-Ion (LiFePO4): The Off-Grid Showdown

For stationary storage, the most useful comparison you can make is against Lithium-Iron Phosphate (LiFePO4). It’s the workhorse lithium chemistry known for being safe and stable. Here’s how they stack up:

| Feature | Sodium-Ion Battery | Lithium-Iron Phosphate (LiFePO4) | The Off-Grid Verdict |

|---|

| Upfront Cost | Lower | Higher | Winner: Sodium-Ion |

| Safety | Excellent (non-flammable) | Very Good (stable chemistry) | Winner: Sodium-Ion (slight edge) |

| Temperature Range | Excellent (-20°C to 60°C) | Good (performance dips in cold) | Winner: Sodium-Ion |

| Energy Density | Lower (heavier/bulkier) | Higher (more compact) | Winner: Lithium-Ion |

| Lifespan (Cycles) | Good to Excellent | Excellent | Draw (both offer long life) |

| Sustainability | Excellent (abundant materials) | Good (no cobalt) | Winner: Sodium-Ion |

The Ideal Customer & Scenario: Who Should Be Using Sodium-Ion Batteries Today?

The takeaway here is pretty straightforward. Sodium-ion is not the answer for every single project, but for some specific jobs, it is an excellent fit.

You should be putting sodium-ion on your radar if your project involves:

- Industrial & Telecom Applications: Powering things like remote cell sites, pipeline monitors, or agricultural gear where you need it to work, hot or cold, without any drama.

- Stationary Commercial Power: Building out large-scale energy storage for solar or wind farms where land isn’t your main constraint and the key metric is your Total Cost of Ownership.

- Critical Backup Systems: Setting up backup power for clinics, community hubs, or other vital infrastructure where the system has to be fundamentally safe and simple to maintain.

On the other hand, you’re still probably better off with lithium-ion for now if your application is mobile or has very strict space constraints where that extra energy density really counts.

Conclusion

So, what’s the bottom line? Is sodium-ion battery a game-changer or still a gamble? For the right application, I believe it’s absolutely a game-changer.

The truth is, there’s no such thing as a “best” battery. It’s always about picking the right tool for the job. If your off-grid project is stationary, and the things you worry about are cost, safety, and performance in bad weather, then sodium-ion is no longer just a science experiment. It is a real, commercially available option that you should be evaluating. And the tech is only getting better, as R&D teams make progress on energy density and manufacturing continues to scale up.

If you’re planning a remote industrial project and are just tired of dealing with price volatility and thermal management headaches, it’s a good time to see how a sodium-ion solution could work for you. contact us today

FAQ

1. Can I just drop sodium-ion batteries into my existing system?

Not really, no. A Na-ion battery has its own way of behaving, its own voltage profile. You’ll need a compatible Battery Management System (BMS) and the right inverter settings. Honestly, you’ll get the best results by designing a new system around it, or by working with an integration expert to handle a retrofit correctly.

2. How does the real-world cycle life of sodium-ion compare to LiFePO4?

Right now, high-quality LiFePO4 has a longer proven track record, and you’ll see a lot of products rated for 6,000+ cycles. That said, the leading Na-ion cells are hitting 3,000-5,000 cycles in the lab with great results. For many off-grid sites that aren’t doing a deep cycle every single day, that kind of lifespan is plenty to be very competitive.

3. What if I buy batteries for a project but can’t install them for six months?

This is actually a perfect scenario for sodium-ion. Because you can take them all the way down to 0% State of Charge for shipping or storage without hurting the cells, they are much, much easier to deal with logistically. This solves a huge headache for projects with long lead times, which can be a real problem with lithium-ion.

4. Do sodium-ion batteries need their own special BMS?

Yes, they absolutely do. Like any modern battery chemistry, a Na-ion pack needs a dedicated BMS that’s programmed for its specific behavior. The BMS is what’s handling the voltage windows, the temp limits, and the cell balancing. You simply can’t use a BMS designed for lithium-ion and expect it to work safely or correctly with a sodium-ion battery.