8 Expert Tips to Supercharge Your Industrial Battery Performance. You’ve made a significant capital investment in a state-of-the-art battery energy storage system (BESS) for your facility. The promise was clear: lower demand charges, reliable backup for critical operations, and a better return on your renewable assets. But if you’re looking at the performance data and starting to get concerned about the real-world lifespan of your battery packs, you’re in the right place.

From my experience working with industrial clients for over 15 years, I’ve seen that the gap between good and great performance often comes down to smart management, not just the specs on a data sheet. This isn’t about needing a PhD in electrochemistry. It’s about smart, on-the-ground operational intelligence.

In this guide, we’ll walk through 8 real-world strategies—from simple BMS settings to operational habits—that will help you maximize performance, extend cycle life, and truly protect your energy storage investment.

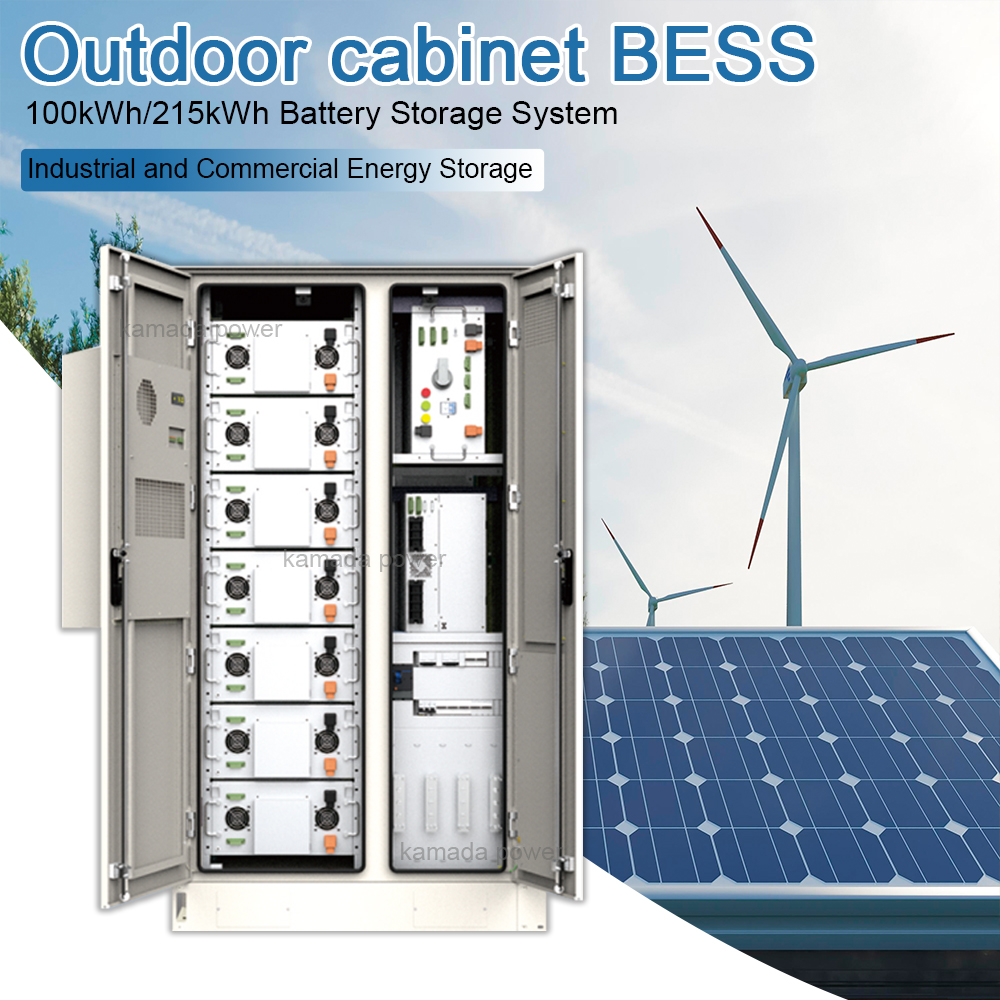

Kamada Power 100kWh Battery Energy Storage System

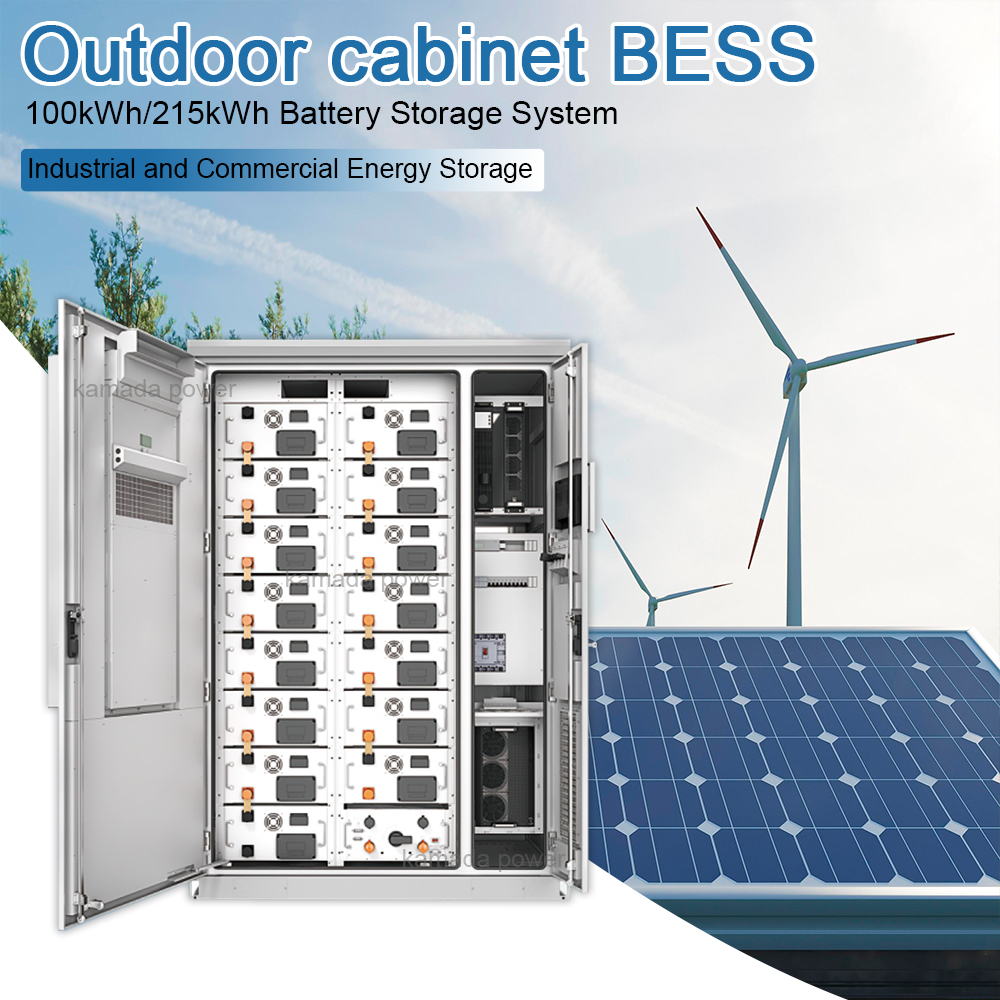

Kamada Power 215kWh Battery Energy Storage System

1. Master Peak Shaving and Load Shifting

For a homeowner, this is about Time-of-Use rates. For your facility, it’s all about demand charges, which can easily make up 30-70% of a commercial electricity bill. The whole game here is programming your BESS to discharge during moments of highest facility-wide power consumption, effectively “shaving” that expensive peak. You can also have the system charge from the grid when energy is dirt cheap (overnight) and use that stored energy to offset daytime costs. A well-configured system can slash demand charges by 50% or more. Frankly, it’s the most powerful financial lever you have.

2. Respect the Depth of Discharge (DoD)

In simple terms, Depth of Discharge (DoD) is just the percentage of the battery’s capacity you’ve used. Consistently running your battery down to empty is one of the fastest ways to destroy it. Think of a fleet of electric forklifts: if operators run them until they die on the warehouse floor every single shift, you can watch the lifespan of those expensive battery packs plummet.

The relationship between DoD and cycle life isn’t linear; it’s exponential. A battery cycled to only 80% DoD might last twice as long as one you consistently drain to 100%. Your Battery Management System (BMS) is your best friend here. For daily peak shaving, configure your BMS to always maintain a minimum State of Charge (SoC) of 10-20%. Consider that buffer your best insurance policy for a long asset life.

3. Control the Climate: Batteries Hate Extremes

Make no mistake, a battery’s operating temperature has a direct say in its performance and lifespan. Most lithium-ion chemistries are happiest around 20-25°C (68-77°F). Installing a BESS in a non-climate-controlled warehouse in Arizona or next to a high-heat process will accelerate chemical degradation. And extreme cold is just as bad, temporarily robbing you of available capacity.

This is a key point during procurement. While a standard LiFePO4 (Lithium Iron Phosphate) pack gives you a great balance of safety and cycle life, it needs active thermal management in harsh conditions. For applications in extreme climates—say, marine backup power in the North Sea or off-grid mining operations—you should look at emerging tech like a sodium-ion battery pack. Sodium-ion often boasts a much wider operating temperature window, potentially saving a fortune on auxiliary HVAC systems and lowering your long-term operational costs.

4. Optimize Your C-Rate

The C-rate measures how quickly your system charges or discharges a battery relative to its capacity. A 1C rate on a 100kWh battery means a 100kW power draw. Your battery is rated for a certain peak C-rate, sure, but running it at maximum output constantly is like redlining a car engine all day, every day. The wear and tear adds up fast. For high-draw industrial equipment, try staggering the startup of large motors or welding equipment. Avoid those sharp, simultaneous power spikes that push your BESS to its absolute limit.

5. Leverage Your Smart Energy Management System (EMS)

The factory default settings on your EMS are designed to be safe and universal, which means they are almost certainly not optimized for your specific facility. You need to spend time with your systems integrator to really dig into the control software. Modern systems can pull in weather forecasts to predict solar generation, learn your facility’s load patterns, and make intelligent charge/discharge decisions on their own. Don’t just set it and forget it—get familiar with the advanced control modes.

6. Conduct Regular “Health Checks” & Software Updates

You have to treat your BESS like any other piece of critical equipment on the floor. Put a simple preventative maintenance schedule in place. Monthly, have a technician glance at the BMS dashboard for any cell imbalance warnings, alarms, or fault codes. Quarterly, do a quick visual inspection to make sure ventilation paths are clear. And this is the part most people miss: always install firmware updates from the manufacturer. They aren’t just for new features; they often contain vital safety patches and algorithms that improve efficiency.

7. Hunt Down Parasitic Loads

In a large facility, these little energy vampires—idle machinery, control panels, standby systems—can add up to a surprisingly large and constant drain on your battery during an outage. Use your energy monitoring system to find your facility’s baseline load when production is shut down. If it’s higher than you’d think, you have a clear opportunity to install contactors or smart controls to truly power down non-essential equipment and squeeze more runtime out of your backup power.

8. Right-Size Your System from the Start

This final point is for anyone in the procurement or expansion phase. An undersized battery is always fighting an uphill battle, constantly hitting high C-rates and deep DoD cycles that will kill it early. An oversized system is just stranded capital with a poor ROI. Before you buy, you must invest in a proper load profile analysis of your facility. Track your energy use in 15-minute intervals for several weeks. That data is absolute gold, and it allows you and your vendor to model the perfect system size for your actual needs.

Conclusion

Optimizing your industrial battery performance isn’t a one-time fix. It’s an ongoing process of smart, data-driven management. When you start focusing on how you use your system—managing discharge depths, controlling for temperature, and smoothing out power draws—you transform it from a static backup box into a dynamic financial asset that actively works to lower your operational costs.

Your first step? Pull up your last six months of utility bills alongside your BESS performance data. Contact us, Let’s schedule a brief consultation to look at that data together and find the single biggest optimization you can make this quarter.

FAQ

What is the typical lifespan of an industrial battery pack?

Most reputable manufacturers will warranty their high-quality industrial packs, especially LiFePO4, for around 10 years or 4,000-6,000 cycles. But honestly, with proper management using the tips above—particularly keeping the average DoD around 80% and ensuring good thermal management—we see these systems exceed their warrantied life all the time, which really improves your total cost of ownership.

Is a higher C-rate battery always better?

Not at all. A higher C-rate means the battery can deliver more power, which is critical for things with high-inrush currents like large motors. The trade-off, however, is often lower energy density (less total kWh for the size) or a shorter cycle life. The goal is to match the C-rate to your application’s real-world power requirements, not just buy the highest number on the spec sheet.

Can I integrate a new BESS with my existing facility SCADA system?

Absolutely, and this is a critical point for integration. Engineers design most industrial-grade Battery Management Systems (BMS) for this exact purpose. They typically use standard industrial protocols like Modbus TCP/IP or CAN bus, which allows your central SCADA system to monitor the battery’s state, health, and performance, and even to control it directly. Make sure this is a key requirement you discuss with any potential vendor.

What if my operation runs in extreme cold, like -20°C?

That’s a tough environment for any battery, but you have options. Extreme cold can slash the available capacity of most lithium-ion batteries, and the BMS will often prevent charging to avoid damage. In these cases, you absolutely must plan for a robust thermal management system (like battery heaters) or seriously evaluate battery chemistries built for extreme temperature performance, such as certain LTO (Lithium Titanate) types or the increasingly viable sodium-ion battery.