How Many Batteries Do You Need? Sizing Your Commercial Battery System. The call comes from the plant manager at 2 AM. A grid failure has halted the production line, and every minute of downtime is costing you thousands. Or maybe you just reviewed last month’s utility bill and the demand charges alone were enough to wipe out your operational efficiency gains. Sound familiar?

These are the real-world scenarios where energy storage isn’t a luxury; it’s a strategic asset.

But the question, “How many batteries do I need?” can feel overwhelming. This guide isn’t about handing you a vague number. It’s about showing you how to calculate your facility’s specific energy needs like a seasoned engineer. We’ll walk through a step-by-step process so you can invest in a system that’s right-sized for your operational goals powerful enough to do the job, but not saddled with the cost of capacity you’ll never use.

20kwh Server Rack Battery

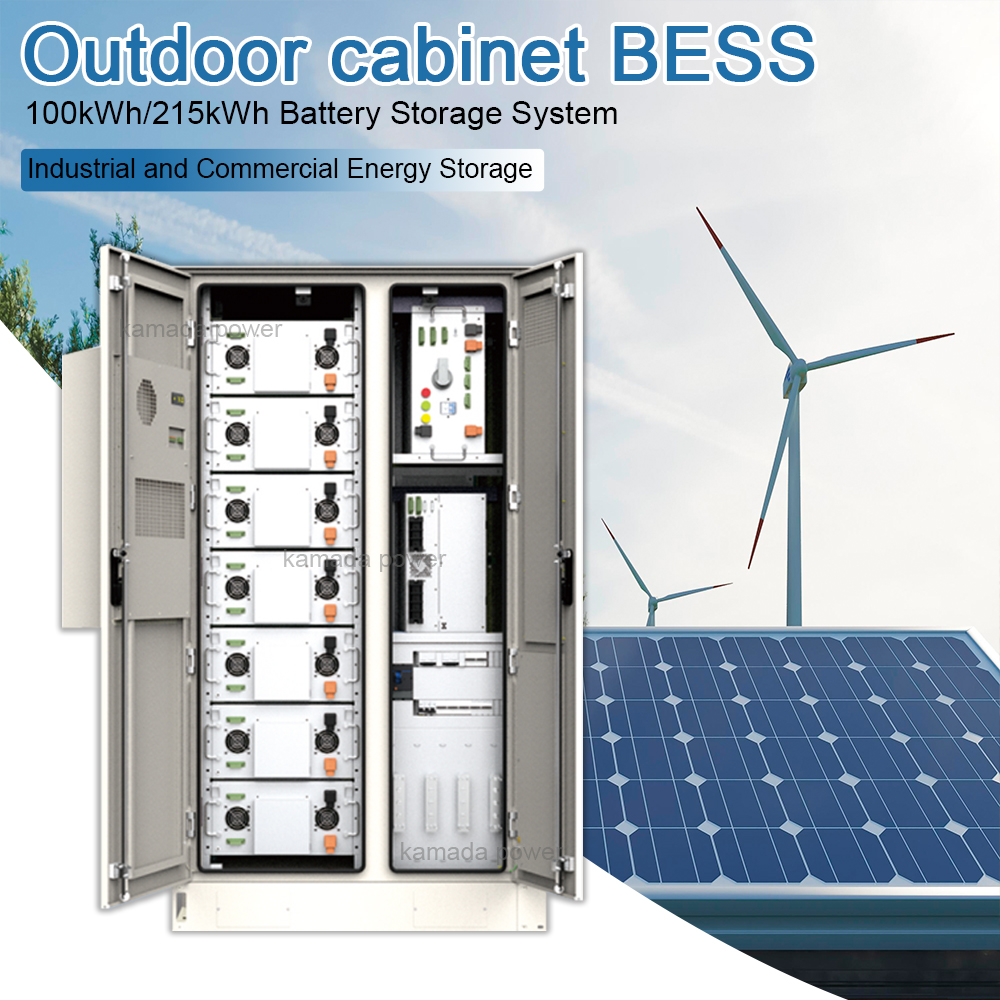

Kamada Power 100kWh battery Commercial Energy Storage Systems

The Foundation: Key Terms You MUST Understand (kW vs. kWh Explained)

Before we can talk numbers, we need to be speaking the same language. Get these two terms right, and you’re 90% of the way there.

What is a Kilowatt-hour (kWh)? Your Energy “Gas Tank”

The easiest way to think about kilowatt-hours (kWh) is as the total amount of energy your battery system can hold. It’s the size of your fuel tank. A 200 kWh system can obviously deliver far more total energy than a 20 kWh one, letting your equipment run for much longer. For a warehouse, this is what determines how many hours you can keep the conveyor belts and lights running after the grid goes down.

What is a Kilowatt (kW)? Your Power “Horsepower”

Kilowatts (kW), on the other hand, measure power—the rate at which your system can deliver energy. This is your engine’s horsepower. You might have a huge 200 kWh tank, but if your system has a low 10 kW rating, it’s not going to start a large industrial motor. The kW rating dictates how much gear you can run at the same time.

Depth of Discharge (DoD): Why You Can’t Use 100% of Your Battery

Depth of Discharge is just the percentage of the battery’s capacity you’ve used. Trust me, you never want to drain an industrial battery to 0%. Doing that consistently will drastically shorten its operational life. Modern chemistries like Lithium Iron Phosphate (LiFePO4) have a great DoD, often 90% or more, which means you get to use more of the energy you paid for without wrecking the battery’s long-term cycle life.

Round-Trip Efficiency: The Energy That Gets Lost in Translation

It’s just physics—when you charge and then discharge a battery, you lose a little energy as heat. Round-trip efficiency simply measures how much energy you get out for every unit you put in. A 95% efficiency means that for every 100 kWh you pump in, you can expect to get 95 kWh of usable power back out. It’s a small but critical detail for calculating your true energy reserves.

Step 1: Define Your Primary Goal (This Changes Everything)

Your end goal is what dictates the entire system design. From our experience with industrial clients, the objectives usually fall into one of these three buckets.

Goal A: Mission-Critical Backup (Operational Continuity)

Here, your top priority is preventing costly downtime. You’re not trying to run the whole facility, just the absolute essentials—server racks, PLC controllers, emergency lighting, security systems. Your job here is to run a critical load analysis to figure out what cannot, under any circumstances, shut down.

Goal B: Peak Shaving & Demand Charge Management

For facilities with power-hungry equipment, like EV charging depots or manufacturing plants, demand charges can be a killer on the monthly utility bill. In this case, you’re using stored energy to flatten your load profile. You charge the batteries when power is cheap (off-peak hours) and discharge them to help power the facility when it’s expensive, “shaving” the peak demand your utility company sees and bills you for.

Goal C: Off-Grid Industrial Operations

For remote assets like telecom towers, mining sites, or agricultural sensors, there is no grid. Your system is the grid. Sizing for this is the most critical of all, because the system has to reliably power the entire operation 24/7 and have enough buffer (autonomy) to ride through several days of bad weather or low solar production.

Step 2: Your Step-by-Step Sizing Calculation

Ready for some back-of-the-napkin math? This simple formula is the same foundation any professional installer will use for a quote.

- List Your Critical Loads & Their Wattage: Identify every piece of equipment you need to power and its consumption.

- Calculate Your Daily Energy Need (kWh): For each device, multiply its power (in kW) by the number of hours it needs to run per day. Add them all up.

- Determine Your Desired Autonomy: How many days of backup do you really need? For critical backup in a city, one day might be plenty. For that remote telecom tower, you might need 3-5 days of autonomy, just to be safe.

- Factor in DoD & Efficiency: Remember, you can’t use 100% of the sticker capacity. We’ll use some conservative, real-world figures like 90% DoD and 95% round-trip efficiency.

- The Final Calculation: Putting It All Together:

Required Battery Capacity (kWh) = (Daily Energy Need x Days of Autonomy) / (DoD x Round-Trip Efficiency)

For example, if your critical loads add up to 50 kWh per day and you want one day of backup, your math would look like this: (50 kWh 1) / (0.90 0.95) = 58.5 kWh. This means you’d need a system with at least that much nameplate capacity.

Beyond kWh: Other Critical Factors

Sizing isn’t just about the kWh number. For an industrial system built to last, you have to think about these things too:

- Power Rating (kW) & Surge Capability: Can the system handle the massive inrush current from starting up large motors or HVAC units? This is a spec you absolutely cannot overlook.

- Battery Chemistry: LiFePO4 (LFP) is the go-to choice for most commercial applications because it’s safe, long-lasting, and thermally stable. But for stationary uses where temperatures get extreme and space isn’t an issue, keep an eye on emerging tech like sodium-ion battery packs. They’re becoming a very interesting alternative.

- The BMS (Battery Management System): Look, a high-quality BMS isn’t just a ‘nice-to-have’; it’s the non-negotiable brain of your system. It protects your very expensive investment by managing everything to maximize lifespan and safety.

- Scalability: Your power needs might grow. It’s smart to choose a modular system that lets you add more battery capacity down the road without having to rip everything out and start over.

Conclusion

At this point, you’re no longer just asking, “how much does it cost?” You’re equipped to have a real technical discussion. You can define your goal, walk a supplier through your load calculations, and ask smart questions about power ratings, chemistry, and the BMS. This knowledge makes you a partner in the project, not just a buyer.

Ready to move from theory to a practical plan? Contact us. Let our engineering team take a look at your numbers with a complimentary load analysis. We can help validate your calculations and spec out a system that truly matches your operational and financial goals.

FAQ

How do I size a battery system for peak shaving?

Sizing for peak shaving is a different beast. It’s less about backup and all about your utility data. You need to get your hands on your interval load data (usually in 15-minute chunks) to see how high your peaks are and how long they last. The goal is a battery with enough kW to knock down that peak and enough kWh to keep it down for the whole peak period.

What’s more important for an industrial application: cycle life or energy density?

For stationary industrial systems like a commercial ESS, cycle life wins that fight nine times out of ten. You need a battery that can deliver thousands of cycles over a 10-20 year lifespan to get your money’s worth. Energy density—how much power fits into a small space—is much more important for things that move, like forklifts or marine vessels.

Can I use my solar array to charge an industrial battery bank?

Absolutely. It’s one of the most effective pairings out there. The trick is making sure your solar array is big enough to both run your operations during the day and fully charge your battery bank before the sun goes down. A system where solar production can’t keep up with both will always be playing catch-up.